This information:

- Shares an overview of the system

- Presents operational patterns

- Illustrates system dynamics

- Identifies approaching challenges

Operational performance (December 2025)

1. Flow volumes at regional plants and key points in the system

The following graphs illustrate the total amount of flow to each of our regional treatment plants over various periods of time including flows through the Combined Sewer Overflow system. The bars at the bottom of the first graph illustrate the impact that rainfall has on our system.

2. Combined Sewer Overflow (CSO) discharge volumes throughout the system

The following graph illustrates the total amount of flow that is handled through the regional Combined Sewer Overflow system. Here is the link that shows our CSO locations:

3. Production and distribution of Loop biosolids

Biosolids are the nutrient-rich product of the wastewater treatment process. Biosolids improve soil fertility and enhance plant growth and crop yield. Loop® is the brand name for biosolids produced by King County. Loop is used as fertilizer and soil amendment for commercial forestry and agriculture, and as an ingredient in compost for landscaping and home gardening.

King County’s biosolids program is responsible for managing Loop recycling, including transportation and delivery, permitting and managing Loop applications, research and monitoring, and public outreach. Since 1973, we have worked with local organizations, farm groups, and university scientists to develop an award-winning program that serves as a model for safe, sustainable biosolids recycling.

4. Electrical energy usage at each regional treatment plant and conveyance system

Monthly Average Electricity Use at Brightwater, South Plant and West Point:

This diagram shows the average daily electricity use for the past 13 months for each of King County’s three main treatment plants. West Point’s electricity use depends mainly on treated volume. South Plant’s electricity use is driven by influent flow and oxygen demand for nitrification. Brightwater’s energy use is higher per gallon treated because of its elevated location, which requires more pumping, higher treatment standards, and stringent odor control requirements.

Electricity Use at Brightwater, South Plant and West Point:

This diagram shows daily electricity use for each treatment plant. It highlights how electricity use can double with high flow volumes at West Point.

Total WTD Offsite Energy Use

This diagram shows the combined energy use of WTD’s more than one hundred offsite facilities. Energy use at offsite facilities is driven by flow volumes and outside air temperatures.

Please note: This information is updated monthly and will have a three-month lag when all of the data becomes available.

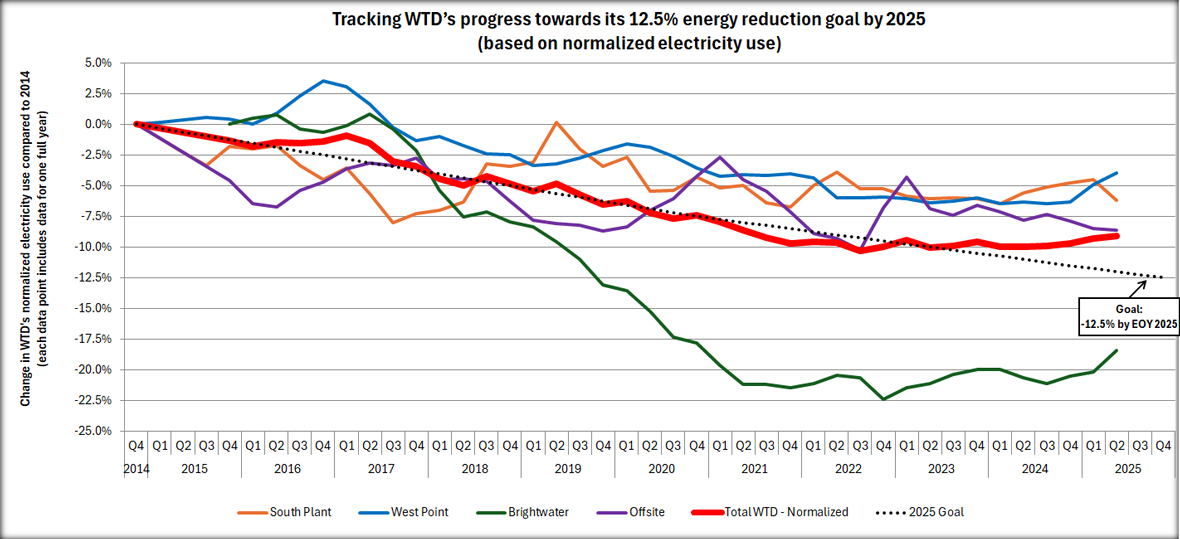

Tracking WTD’s progress towards its 7.5% energy reduction goal.

Normalized electricity use describes the amount of electricity a facility would have used if the general conditions had been the same as they were in the baseline year (2014). Normalizing energy use allows us to track changes in energy use independent of factors we do not control such as air temperatures or flow volumes. This diagram shows the change in normalized electricity use for each treatment plant, offsite facilities and WTD in total and how these changes compare to the County wide 2020 energy reduction goal.

Please note: This normalized electricity use information is updated once a quarter with a lag time of about three months.

5. Production and usage of biogas

WTD, Biogas Utilization

Biogas is used differently at each of the three treatment plants.

- At South Plant excess biogas can be fed into PSE’s natural gas pipeline.

- At Brightwater and West Point biogas usage is limited to the equipment on site. At both of these plants there is a higher demand for biogas in winter when flows are higher and temperatures lower. The total amount of biogas beneficially used therefore tends to be higher in winter than in summer.

Regulatory performance (December 2025)

6. Significant power disruption events

The following table conveys information on the performance of the County’s wastewater treatment facilities and conveyance system for any monthly exceedances of permit requirements that are caused by power disruption or involve events with backups of the conveyance system and need for substantial responsive actions (e.g., cleanup of sanitary sewer overflows).

7. Significant system process disruptions

The following table conveys information on the performance of the County’s wastewater treatment facilities and conveyance system for any monthly exceedances of permit requirements that are caused by, or involve, process disruption (not power related) such as major equipment or biological treatment process failures, or industrial discharges.

8. Regulatory compliance and performance

The following table conveys information on the performance of King County’s wastewater treatment facilities and conveyance system for any monthly exceedances of permit requirements that involve compliance with effluent limitations at the County’s five wastewater treatment plants or four CSO treatment facilities, or unpermitted overflow events in the separated sanitary or combined stormwater-sewer conveyance system.

9. Water quality monitoring

King County WTD conducts routine effluent water quality monitoring for compliance with the NPDES permit requirements at the County’s five wastewater treatment plants, and at the four CSO treatment facilities. Additionally, WTD (in conjunction with scientists in King County Water and Land Resources Division [WLRD]) conducts specific sediment and water quality monitoring studies required for compliance with the NPDES permit as well as the Post Construction Monitoring Program for the County’s 2012 Long-term CSO Control Plan Amendment. The following sections further describe these monitoring programs and provide information on the status of currently available monitoring efforts and data reports.

Effluent Monitoring Data

WTD monitors treated wastewater (effluent) at each of the five main treatment plants (West Point, South Plant, Brightwater, Vashon, and Carnation) for a variety of conventional chemical and biological water quality properties which are used to track performance of the physical and biological treatment processes, and to ensure compliance with effluent limitations that are specified in the NPDES permit for the purposes of protecting the aquatic environment where the wastewater is discharged. WTD also conducts required effluent monitoring at the four CSO treatment facilities (Carkeek, Elliott West, Alki, and Henderson/Martin Luther King [H/MLK]) whenever wet weather storm events result in these facilities operating and discharging to their designated CSO outfalls. The majority of the routine effluent data that is collected to comply with applicable NDPES permit requirements is compiled and submitted to Ecology electronically as Discharge Monitoring Reports (DMRs) on a regular monthly basis.

The key parameters that are monitored for NPDES permit compliance with effluent limitations consist of biochemical oxygen demand (BOD), total suspended solids (TSS), settleable solids, pH, chlorine residual, and fecal coliform bacterial. The compliance with the effluent limitations is a primary method used by Ecology and WTD of evaluating routine and ongoing performance of the treatment processes. Accordingly, the reader is directed to review information presented above under “#8 –Regulatory Compliance and Performance” which provides a simplified summary of monthly plant performance that incorporates and interprets the diverse set of effluent monitoring data and information on any significant non-compliance events.

The effluent monitoring data and reports submitted to Ecology in monthly DMRs address many additional parameters that are not necessarily directly attributable to treatment process performance or NPDES regulatory compliance. However, the following attached files are the cover letters submitted for the most recent DMRs for each of the five wastewater treatment plants. The cover letters characterize each facility during the monitoring period including such items as flows, compliance with NPDES permit requirements, and any other important process performance events, news, or significant events. The facility DMR cover letters for the most recent monthly monitoring period follow:

- Brightwater (Permit No. WA0032247)

- Carnation (Permit No. WA0032182)

- South Plant (Permit No. WA0029581)

- Vashon (Permit No. WA0022527)

- West Point (Permit No. WA0029181)

Finally, the entire body of effluent monitoring data and reports that are submitted to Ecology as part a DMR package are available on Ecology’s “PARIS” database by searching on the Permit No. for each plant (identified above) at the following: https://fortress.wa.gov/ecy/paris/PermitLookup.aspx

WTD also conducted additional effluent monitoring during the restoration process for the West Point treatment plant following the February 9, 2017 flooding and damage incident. WTD established a dedicated temporary webpage to post the collected effluent data, summaries of the data, and other reports and information. With the restoration of the majority of treatment processes and equipment completed in May 2017, and West Point’s return to its normal status of routine compliance with permit requirements, the additional monitoring was discontinued and WTD now intends to maintain the temporary webpage indefinitely until such time it is determined to no longer be necessary.

Water Quality Monitoring Data

The County’s Water, Resources, and Land Division (WRLD) – Science Section, with assistance from the King County Environmental Laboratory (KCEL), conducts a variety of water quality monitoring programs in the Puget Sound, and the regions rivers and lakes that indirectly contribute to an understanding of the effects of County activities on environmental resources. However, with the exception of limited periodic and specific discharge event conditions, the County is not required under the NPDES permits for the wastewater treatment plants to conduct receiving water quality monitoring at our discharge outfall locations. Consequently, the reader is directed to the WLRD Science Section website where available information on the ambient marine water quality monitoring programs in Puget Sound can be found: https://green2.kingcounty.gov/marine

Additionally, WTD in conjunction with WLRD Science Section staff, temporarily expanded and increased the frequency of the routine marine water quality monitoring in Puget Sound at sites near the West Point outfall while the restoration process for the West Point treatment plant was underway following the February 9, 2017 flooding and damage incident. WTD established a dedicated temporary webpage to post bi-weekly summary reports of Puget Sound water quality conditions during this period, and with West Point’s return to a state of compliance with NPDES permit requirements, the additional monitoring was discontinued in June 2017. Furthermore, WTD and WLRD Science Section are involved in conducting supplemental environmental analyses to characterize conditions in Puget Sound resulting from the West Point incident to determine if any changes in contaminants of concern may have occurred in sediments or marine aquatic organisms.

Sediment Monitoring Data

WTD, with assistance from the WLRD Science Section, conducts extensive sediment quality monitoring and analysis for compliance with the NPDES permits for the West Point, South Plant, and Brightwater treatment plants. A large amount of the County’s required sediment analysis work is conducted at CSO outfall locations to implement the Post Construction Monitoring Program for the County’s 2012 Long-term CSO Control Plan Amendment under the West Point NPDES permit. The CSO program is focused on ensuring that the CSO outfalls meet Washington’s sediment quality standards as hydraulic control of each outfall is achieved (i.e., not more than one overflow event per year on a 20-year average). The West Point NPDES permit also requires the County to prepare an update of the 2009 Sediment Data Report by December 1, 2018 to provide a comprehensive summary of information for each CSO outfall and its status with respect to compliance with sediment quality standards. Finally, the County is implementing, and periodically updates, a Sediment Management Program that provides the overarching direction for all of the CSO discharge locations, summarizes ongoing and previously performed sediment cleanup work, summarizes the results of CSO discharge modeling, provides the status of existing sediment quality, and assigns an appropriate sediment management strategy for each CSO. In general, the sediment investigations and development of sediment management strategies at any given CSO outfall is a complex and lengthy process involving multiple actions and participants, and summary information on the status of each project is not readily summarized. Consequently, the reader is directed to the County’s dedicated Sediment Management Plan website where available information, reports, news, and status of the program can be obtained: Sediment management plan

Financial performance (December 2025)

10. Wastewater planned revenue and use of revenue

This chart compares WTD planned revenue and use of revenue with monthly actual revenue and use of the revenue collections. Monthly actuals highlight total revenue collected by the sewer rate, capacity charge and other sources, and total use of the revenue collected by operating expenditures, debt service and transfer to capital.

11. Cost and schedule of baselined major capital projects

This table represents budget and schedule performance of projects with greater than $1M expected cost. Performance is measured relative to the baseline point which is established at approximately 30% design completion per established King County Project Management Standards.

Safety performance (December 2025)

12. WTD accident (claim) summary

The following summary graphs illustrate employee accident and job injury claim experience (for current month and year to date) for the Wastewater Treatment Division.

WTD Claims Summary

- The term Medical Only Claim refers to employee accident that requires attention from a healthcare provider. The injured worker may be released completely after treatment or released with work restrictions requiring work accommodation.

- The term Timeloss Claim refers to claims that are serious enough to warrant the doctor taking the injured worker off his regular duty for a period of time. The injured worker may be released to modified (light) duty during his recovery period. As long as the employer accommodates the doctor’s restrictions on the injured worker’s activity during the light duty period, the claim may remain as medical only – if the injured worker returns to light duty before the elimination period lapses.

Monthly archives

Note: if you would like a monthly archive from 2023 to 2017 (web page launch), send a request to wtdweb@kingcounty.gov.

Translate

Translate