Management of these assets includes planning, design, procurement, maintenance, repair, refurbishment or replacement of sewer lines and equipment at pump stations and treatment plants to avoid sewer overflows, and to keep our staff and the public safe. WTD is committed to meeting all regulatory requirements and fulfilling our customer’s expectations while minimizing the total cost of the system.

Much of the King County wastewater treatment system is over 50 years with many assets reaching “end of life” each year. WTD uses objective and measurable criteria to prioritize asset management projects so that we can plan and forecast the maintenance or replacement of critical assets.

February 2026

Updated metrics are currently unavailable due to transitioning to new database software, WTD expects to have updated metrics Q3 2026.

For questions, please contact Alden Wyma, WTD Asset Manager, at 206-477-5601 email alden.wyma@kingcounty.gov or Dave Jurgens, Wastewater Treatment Plant Manager, at 206-263-1786 email david.jurgens@kingcounty.gov.

Status of key areas of Asset Management Program (August 2025)

WTD Assets

Asset Registry

The Asset Registry is the database of physical assets in our maintenance system. The database includes multiple attributes of our assets to help us maintain and analyze our value-added activities to extend useful life of the asset.

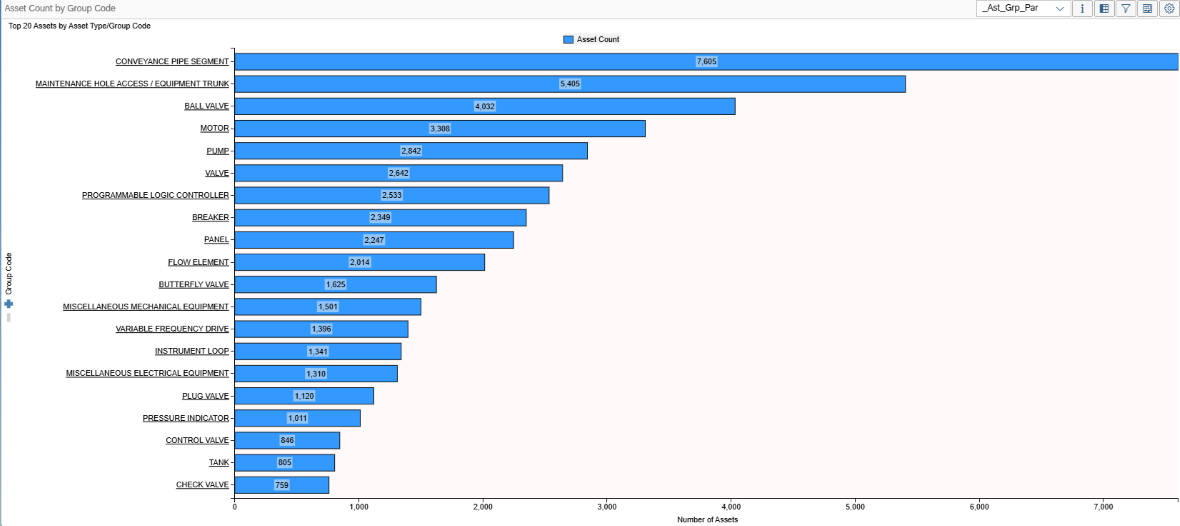

Below is a graph of the top 20 assets by asset type or group code.

Top 20 assets by Asset Type or Group Code

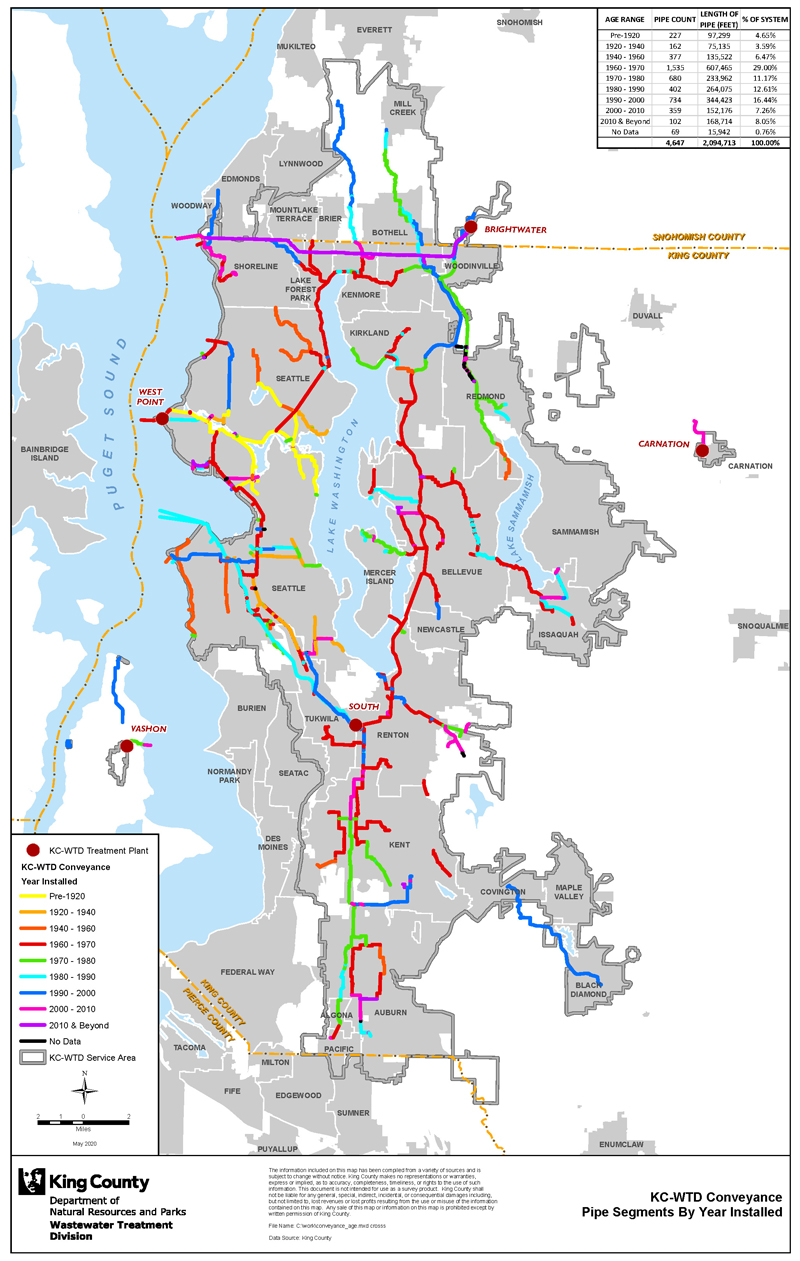

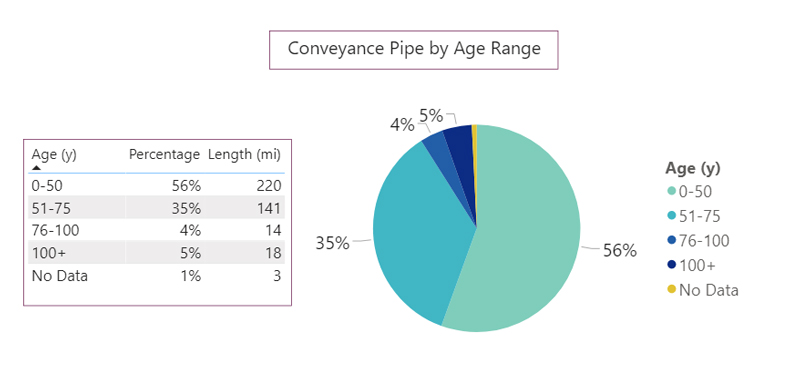

Conveyance Pipe Age

Conveyance Pipe by Age Range

KC-WTD Conveyance Pipe Segments By Year Installed

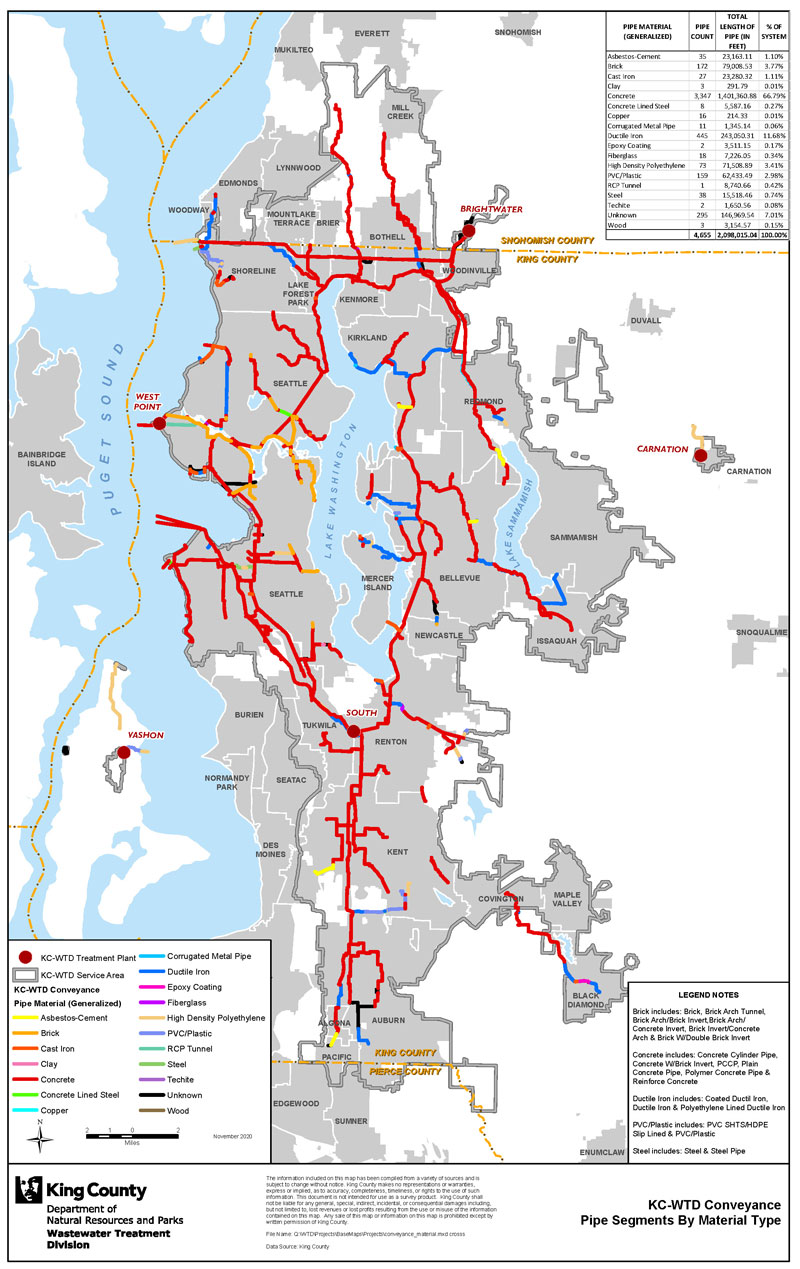

Conveyance Pipe Material

KC-WTD Conveyance Pipe Segments By Type of Material

How we maintain

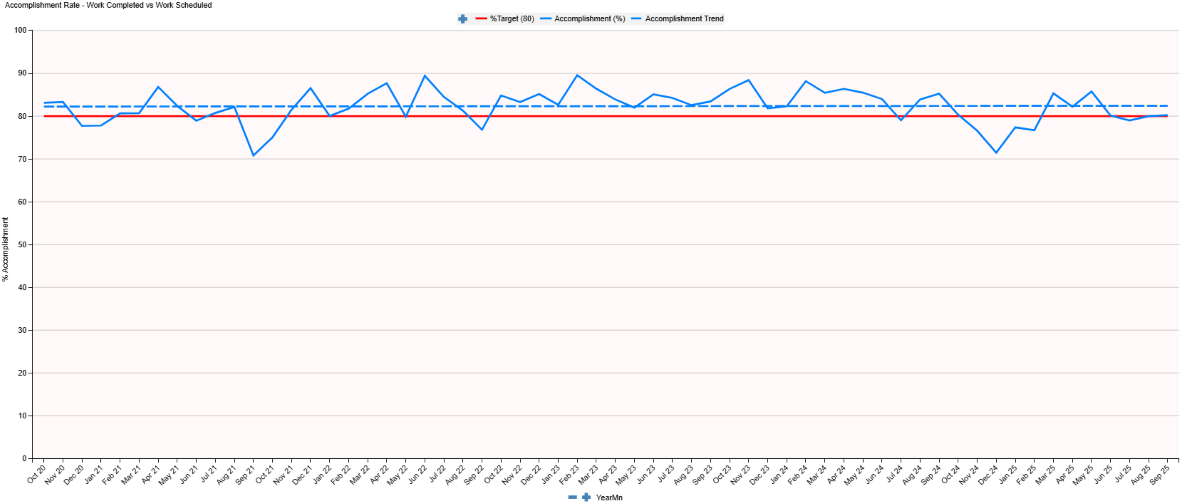

Scheduling allows us to implement proactive maintenance strategies while simultaneously coordinating short-term/unexpected work. By measuring the accomplishment against the schedule we develop a weekly feedback loop to increase completion and address roadblocks. This helps us to:

- Review the backlog of work to make sure we are addressing the highest priority items.

- Coordinate maintenance activities with affected groups to promote efficiency (maintenance, operations, etc)

Below is a chart documenting the accomplishment rate.

Maintenance Work Accomplishment Rate – Work Completed vs Work Scheduled

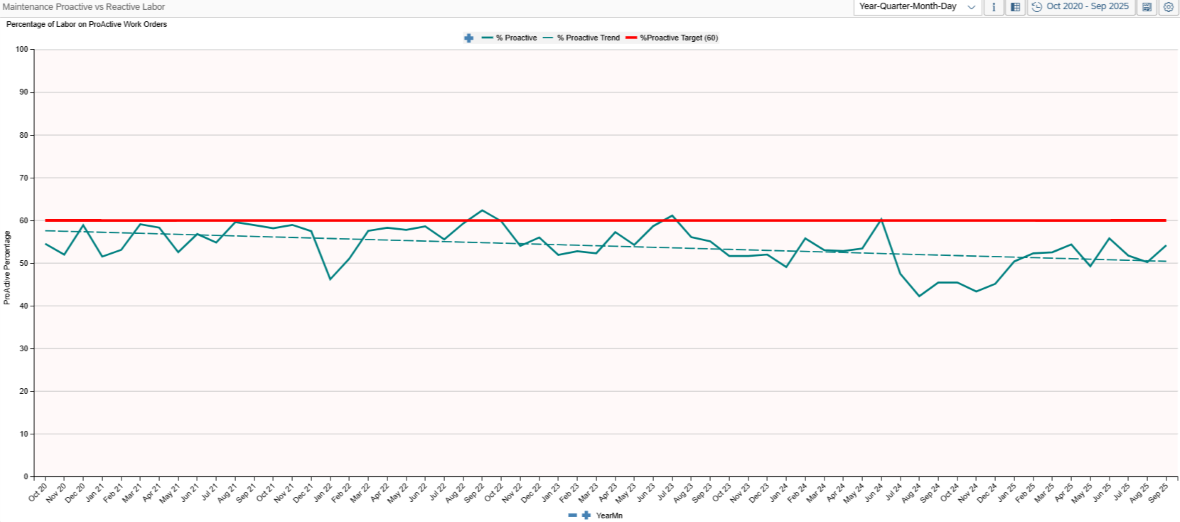

Proactive activities are documented maintenance strategies that we have to avoid or detect failure before it affects our system. Reactive activities are when our assets are telling us what they need. We are always in a continuous improvement process to:

- Learn what our assets need to proactively address them

- Reduce our reactive maintenance to improve reliability and decrease operating costs

Below is a chart documenting the percentage of our labor hours against proactive work.

Percentage of Maintenance Labor on Proactive Work Orders

Eyes on our current assets

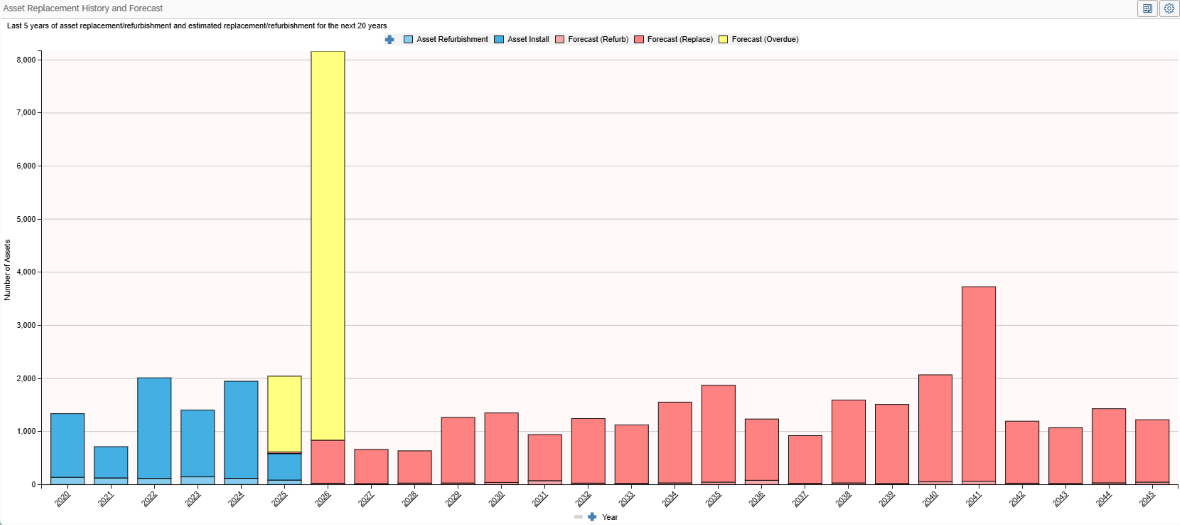

WTD is in the process of estimating the useful life of our 60,000 assets. This estimation allows us to:

- Determine a condition assessment cycle to assess both the individual asset and it’s estimated useful life.

- Proactively refurbish or replace them to maintain our high levels of service.

- Track assets to ensure needed work is completed and issues are addressed in a timely manner.

The graph below depicts the magnitude of assets refurbished or replaced in past years as well as a forecast (using the estimated useful life) of assets to be refurbished or replaced for planning purposes. Areas in yellow indicate backlog of assets that are operating beyond their estimated replacement/refurbishment date. These assets have a medium to low priority because they are still in good condition, meet performance standards and have a low criticality within the system. These assets may require increased maintenance attention to ensure reliability.

Translate

Translate